Drilling titanium in smallest diameters

The trend towards miniaturization requires ever tinier high-performance tools that guarantee reliable processes and maximum precision. This also applies to the machining of titanium.

Titanium is a difficult material to machine, its high toughness and strength resistance and the low thermal conductivity are just some of the characteristics, which leads to be capricious when machining it.

With CrazyDrill Titanium TN / TK, Mikron Tool offers a micro drill perfectly tailored to pure titanium and titanium alloys in the diameter range of 0.2 to 2 mm (.008“ to .078“, fractional inches available) and for drilling depth of 3 x d and 6 x d. These high-performance tungsten carbide drills can also be used reliably in machining scenarios with low internal cooling pressure or with external cooling and are available in two versions: CrazyDrill Titanium TK with through shank cooling (min. 15 bar or 220 psi) and CrazyDrill Titanium TN for the machining with external lubrication.

CrazyDrill Titanium TK – through shank cooling

The challenge: High thermal load

When drilling titanium, the high thermal load on the cutting edge poses a challenge. This leads to chipping of the cutting edge and increases the tool wear. Best cooling technologies for drills bigger than 1 mm (and availability of min 40bar coolant pressure) are twisted internal cooling channels, exiting on the drill tip. For drill diameters from 0.2 mm other technologies to ensure a stable and reliable drilling process should be found!

Solution: Through shank cooling

The actual cooling technologies don’t permit to apply spiralized cooling channels-system on micro drills which would need extremely high pressures. The solution of Mikron Tool is the CrazyDrill Titanium TK with through shank coolant system, that permits to apply massive coolant, allowing the heat to dissipate and thereby to guarantee a long tool life. The continuous coolant jet ensures also best chips evacuation. In addition, the system can be used with a minimum pressure of 15 bar.

Apart from this product, Mikron Tool also offers, upon request, CrazyDrill Titanium TN as solution for external lubrication.

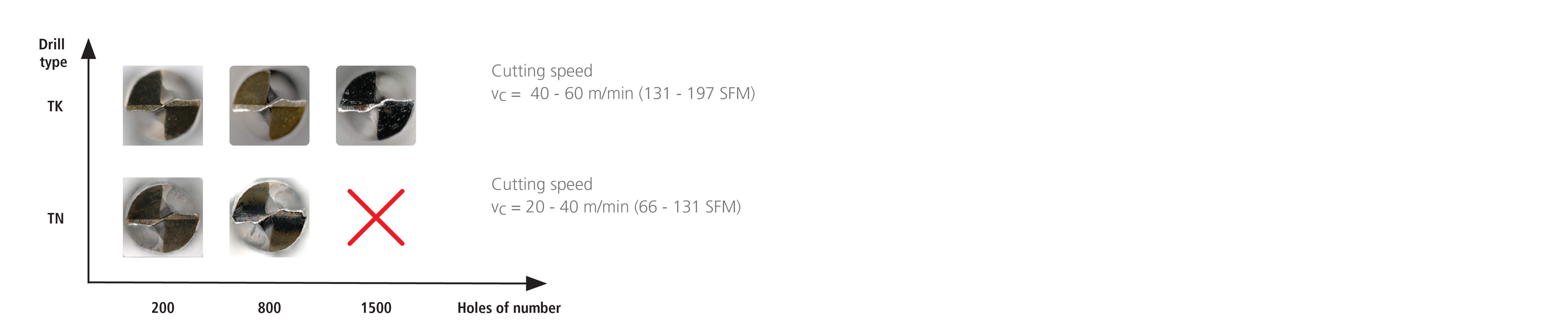

Comparison between through shank cooling and external lubrication:

Specific cutting geometry

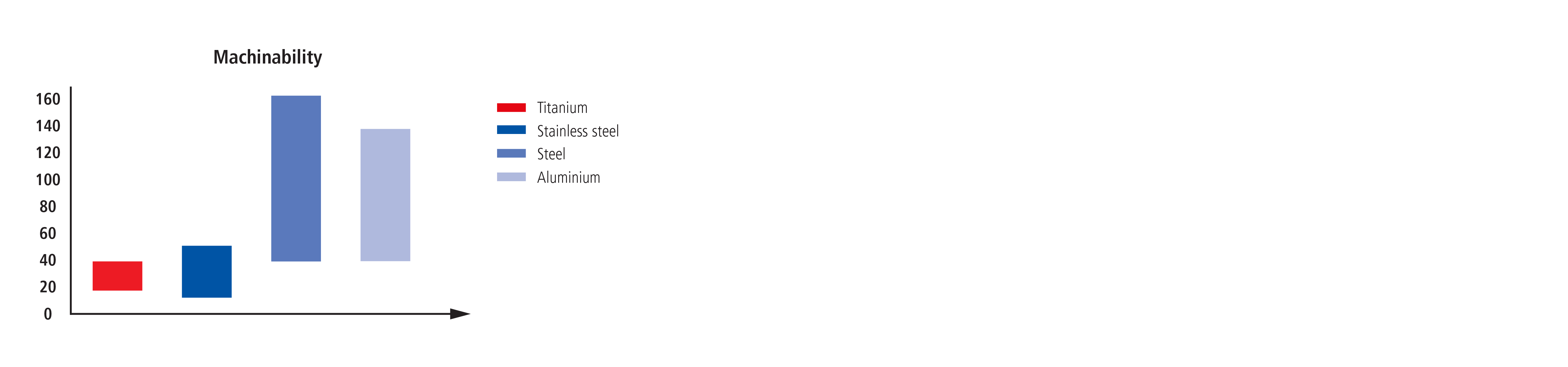

Challenge: Low machinability of titanium

The machinability of titanium is generally more difficult than other materials as steels and stainless steels. A special cutting geometry is essential to machine titanium effectively and efficiently.

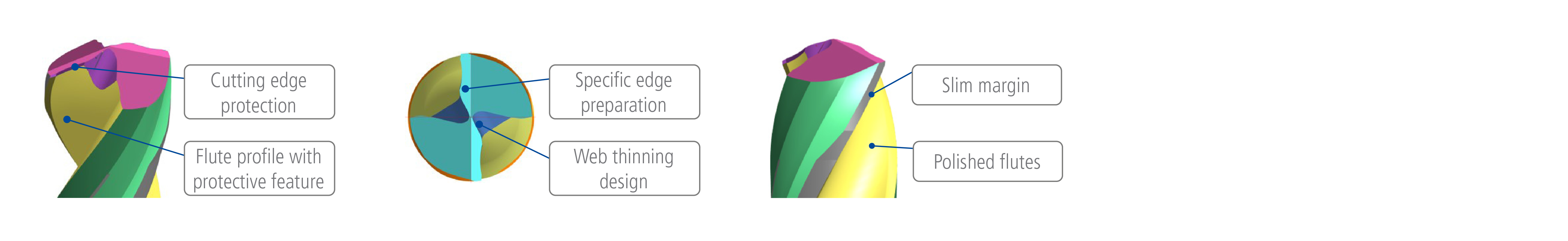

The solution: Specific cutting geometry for all grades of titanium

Taking advantage of the pecking strategy and applying a cooling concept through the shank, Mikron Tool developed one single geometry suitable for all titanium grades, with the following characteristics:

Advantages:

- Good self-centering

- Process reliability

- Perfect chip evacuation

- Reduced material adhesion

Low cutting forces and reduced axial forces

The challenge: High axial forces

A conventional cutting tip geometry with large web creates high axial force that leads to part bending. Even worse in case of overhanging and thin-walled work pieces.

The solution: Specific titanium drill tip design

CrazyDrill Titanium TK/TN is engineered with extreme small web thinning and specific cutting-edge design for drilling with low axial forces. The result is a 25% to 45% force reduction.

Example:

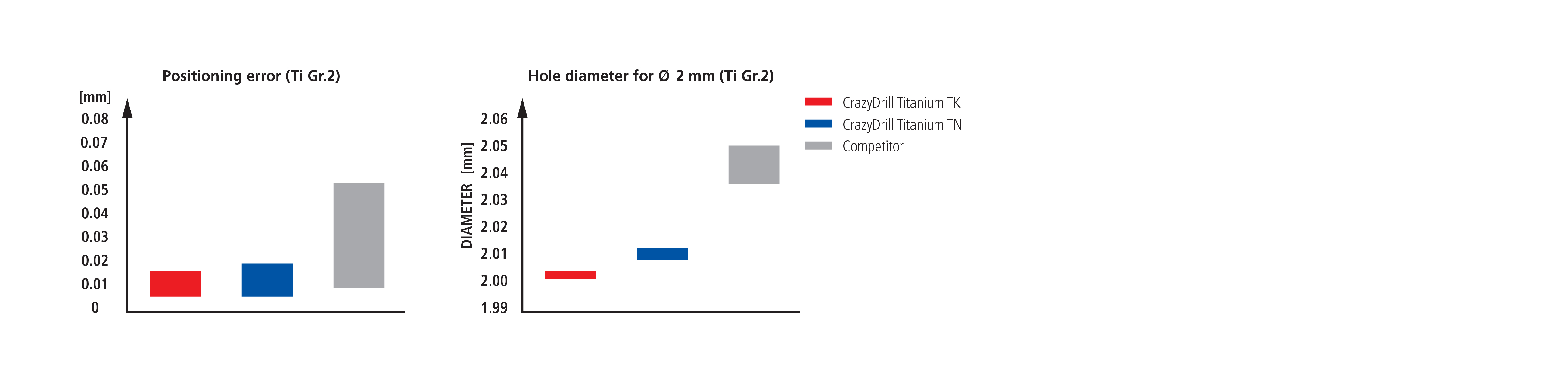

Highest precision

The challenge: High hole accuracy

Titanium has a high elasticity and tensile strengths. Therefore, the requirements to achieve good surface quality, accuracies in diameter, roundness, and position are very high.

The solution: Specific titanium drill design

A perfect combination of design for best results:

- Drill tip / web thinning: - low axial force - good positioning & low deviation

- Slim margin: - avoiding of material adhesion - good surface quality

- Cutting edge with protection: - stable cutting edges (no breakage) - precise hole diameter

Your personal CrazyDrill Titanium TN/TK

Mikron Tool also offers CrazyDrill Titanium TN/TK in customer-specific executions:

- Counterclockwise drill

- Drills with varying drill size diameters and lengths for the standard program

Do you need more information about our possibilities? Contact us here.