Why Mikron Tool

Top performance in small dimensions

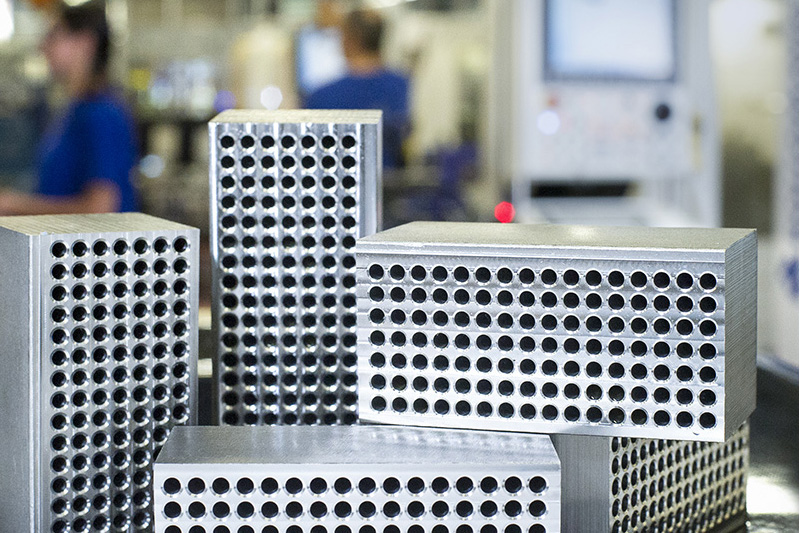

Mastering every step of carbide tool manufacturing

Mikron Tool has achieved an excellent reputation as manufacturer of innovative tungsten carbide tools in the highest quality field. To justify this reputation and to maintain it in the long run requires the constant efforts of the entire team. Machining carbide means for us everything, from defining the geometry, through the grinding and up to the coating as well as the pre-processing and post-processing of the tools.

Innovative and specialized

Important for us is a high competence in everything we are doing. This is possible by specializing ourselves in a core area. Our strength is in the machining of smallest drill bits (from 0.1 mm (.004") drills), with focus on materials that are difficult to machine (e.g. from drilling of stainless steel and up to deburring of stainless steel, also drill bits for hardened steel, including all possible processing operations). To this purpose, we always offer new maximum solutions to our customers. In order to achieve highest precision, process reliability or processing speed, we are looking for the right raw materials and coatings, define the perfect geometries, test the cutting parameters and optimize the processes.

Repeated precision in the µ-range

Thanks to the most modern means of production and measurement instruments, we are in a position to manufacture not only tools with a precision of +/- 0.0005 mm (.00002") but also to maintain the precision of the processing within this tolerance spread. And this is not only once. At any reordering, the customer has the guarantee to receive an identical tool which obtains the same results when used with the same cutting parameters. This is unique worldwide.

High performance

The tools of Mikron Tool always guarantee the highest performance, no matter if it is for customer-specific solutions or standardized products. Here "High Performance" means high processing speed, long tool life, high process reliability or excellent quality results. These arguments often go hand in hand and offer clear added value to the user. He can reduce significantly the cost per part.

Top quality from A to Z

We owe the high product and service quality to a motivated team which consists of developers, tool specialists, materials scientists, grinding specialists and technical sales representatives. For us the quality is more than the manufacturing of top products. The quality appears during the first contact with a potential customer, passes through the offer up to the grinding of the tool, from the packaging and shipping, through the image at trade fairs and up to the means of communication. Every employee in our company has a commitment to the quality, everyone bears full responsibility for his work.

We require top quality also from our partners and thus we work only with the best carbide suppliers and coatings specialists.

The certification according to the ISO standards is self-evident for us. Since 2000, since the first ISO 14001 certification, we have been working continuously on the quality of our processes, their reliability and environmental compatibility. We are now in possession of all important certificates in our industry (ISO 9001; ISO 14001 and OHS 18001).

We are learning from and with the customers

An important element of our way of working is customer contact. Customers have confidence in our solid carbide drill bits with their long lifetimes and excellent cutting properties. For many comprehensive tools engineering is very important. Mikron Tool is particularly strong and flexible in this respect. Together with our customers, we develop products, perform machining tests and consult with them about the high-volume production. And our commitment does not end here; when we say engineering, we understand also the observation of the manufacturing process as well as the optimization of the processes and the tools during their use in production.

Service is in the center

In short, we implement the comprehensive service principle: We accompany, consult and support our customers in the course of the entire lifespan of the product.

Together with the engineering, the further offerings build a multi-service package: The testing of the tools as well as QC records belong to it just as the re-sharpening of worn tools and the customer-oriented logistics service.

Logistics means close to the customer

The fast and easy delivery channels to the customers are important to us: The complete product palette is available also from our stock in Germany and is distributed quickly and without customs formalities within the entire Euro area. Our subsidiary in the USA and China have their own inventory for customers in their country.

References

Our customers include important OEMs and sub-suppliers of the automobile industry, known brands of the watchmaking industry or global suppliers of implants and instruments in the medical and dental areas. There is a cooperation also with various Machine Tool manufacturers which can provide their customers with optimal tooling on the basis of the tools from Mikron Tool from the beginning. Are you curious about more details? Contact us here.