For each type of titanium,

there is a drill to suit

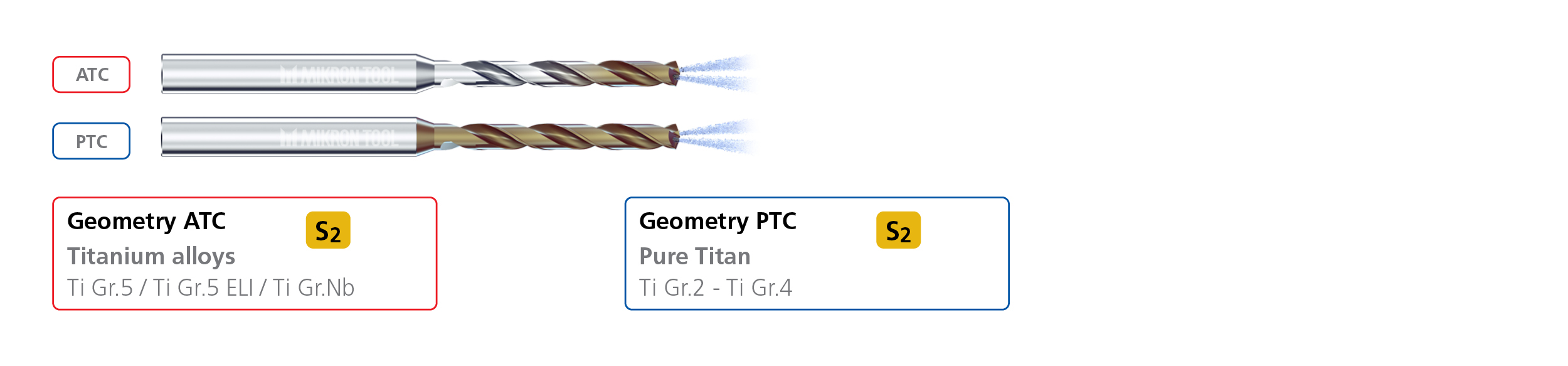

The high-performance material titanium often presents a challenge for machining. Nevertheless, not all titanium is the same. With CrazyDrill Cool Titanium ATC (for titanium alloys) and PTC (for pure titanium), Mikron Tool offers a drill perfectly tailored to the material in question in the diameter range of 1.0 to 6.35 mm (.039“ to .250“, fractional inches available) and for drilling depths of 3 x d to 10 x d. The carbide drill is designed with internal helicoidally arranged cooling channels (drill with through-tool cooling), which bring up to four times more coolant volume to the drill tip. Thanks to the innovative tip and flute geometry and the new type of coating, it is now possible to drill titanium alloys up to a drilling depth of 10 x d in one single step with high performance in terms of quality, tool life, and machining time.

CrazyDrill Cool Titanium – two material-specific geometries for pure titanium and titanium alloys

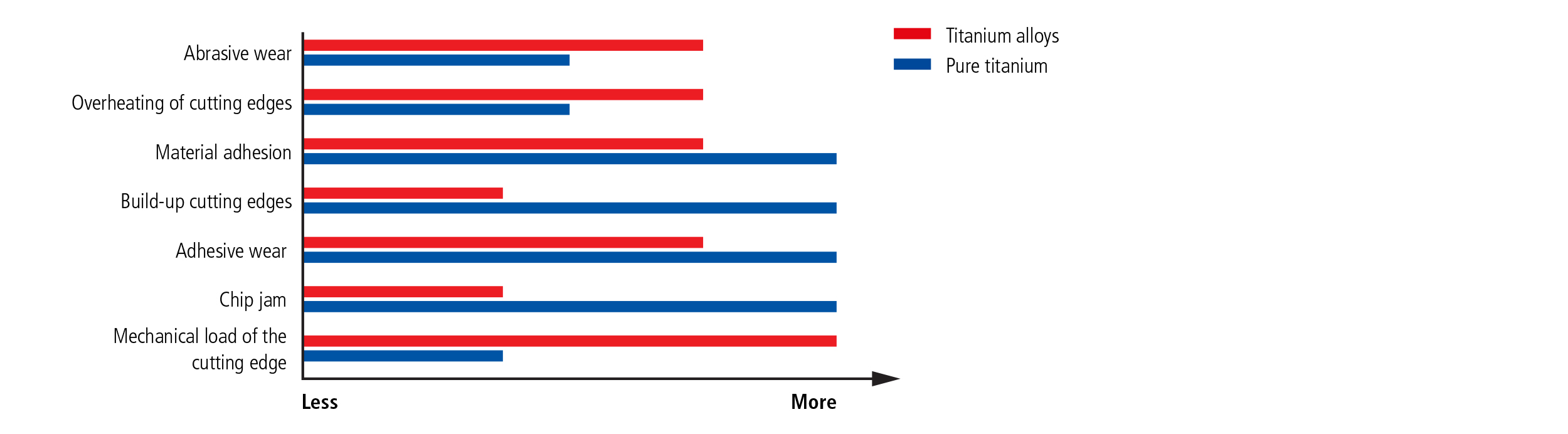

The challenge: The differing properties of pure titanium and titanium alloys

The material properties of pure and alloyed titanium differ significantly. Pure titanium (grades 1-4) is highly corrosion-resistant but has lower mechanical properties. Alloyed titanium (grade 5 and above) is very strong but not very ductile.

Solution: two material-specific cutting-edge geometries

This is the only way to achieve controlled chip removal, high drilling speeds, and repeatable processes with excellent borehole quality in pure titanium and titanium alloys.

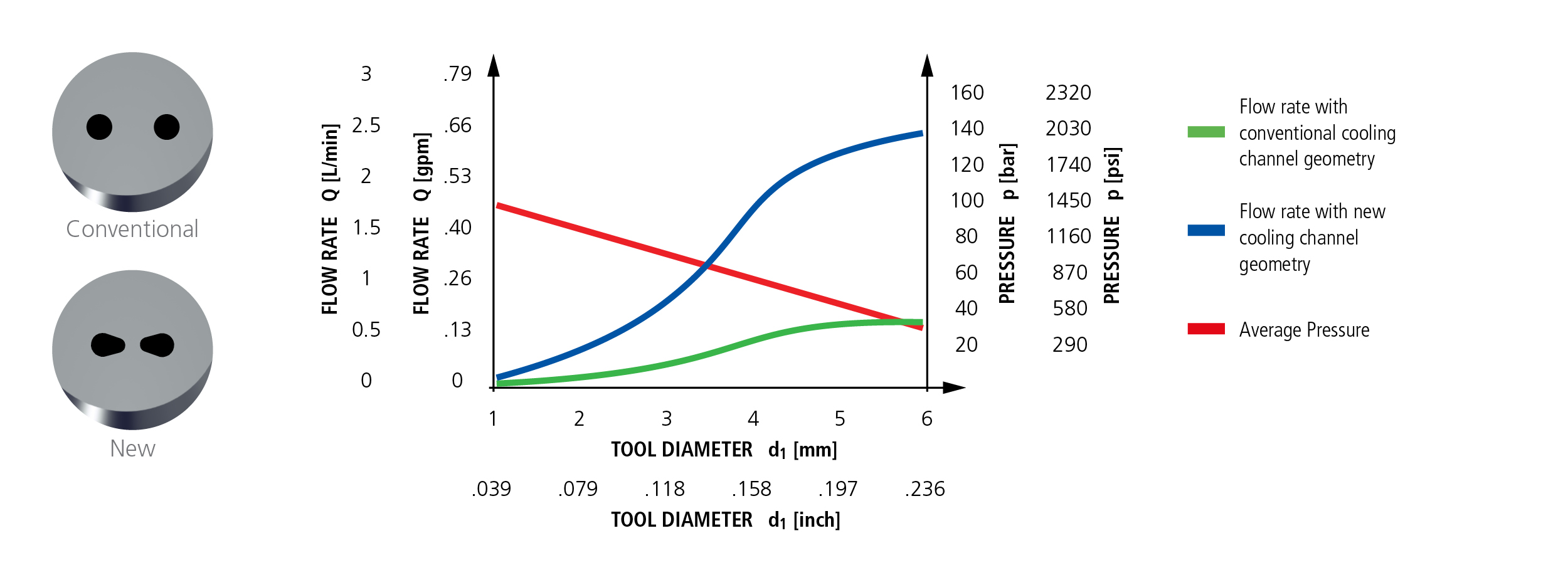

Innovative cooling concept

The challenge: High thermal load and chip jam

High thermal load on the cutting edges can be a challenge when drilling titanium. Potential consequences: Micro-chipping and cutting-edge chipping. Furthermore, titanium chips tend to compact in the drill tip, preventing any subsequent chips from flowing out. This often results in uncontrolled drill breakage.

The solution: Innovative cooling concept

The patented special shape of the cooling channels enables up to 4 times higher coolant quantity (compared to conventional cooling channels) at the same pressure. At the same time, the massive coolant jet flushes the chips through the flutes and prevents any form of chip jamming.

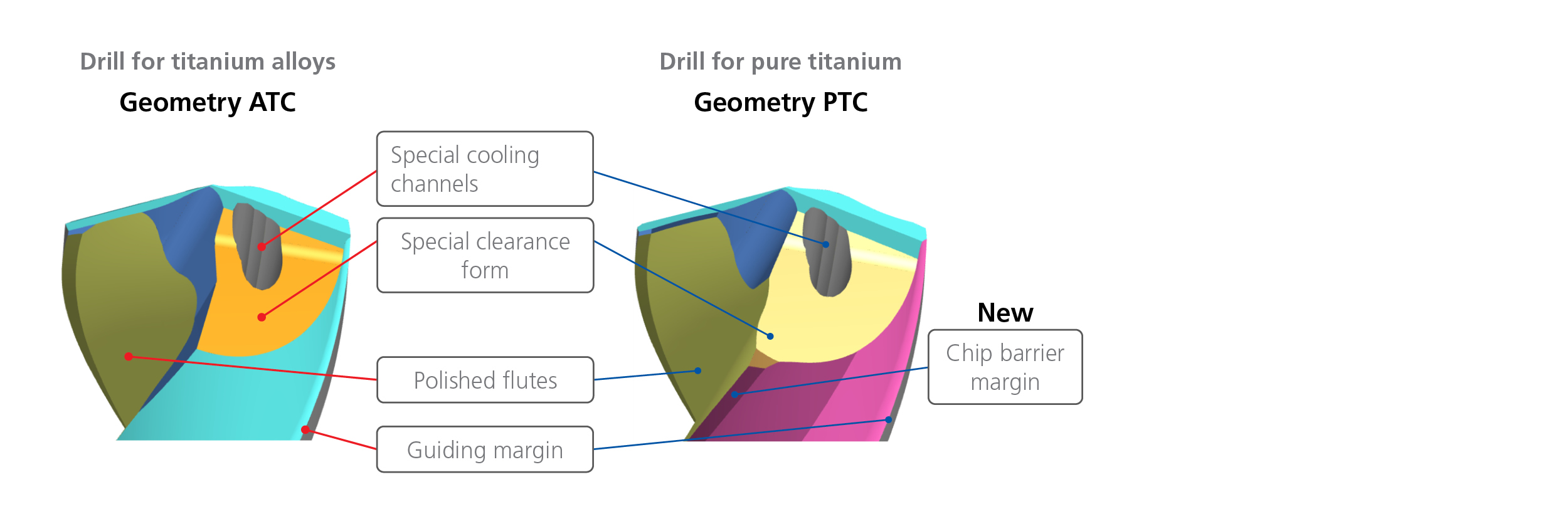

Guiding margins and the newly designed chip barrier margins

The challenge: Material adhesion

Material adhesion on the guiding and secondary margins increase cutting force and negatively affect hole quality.

The solution: Guiding margins and the newly designed chip barrier margins

The particularly smooth surfaces of the guiding margin and the newly designed chip barrier margin on the PTC drill prevent material from sticking and thus reduce the load on the tool.

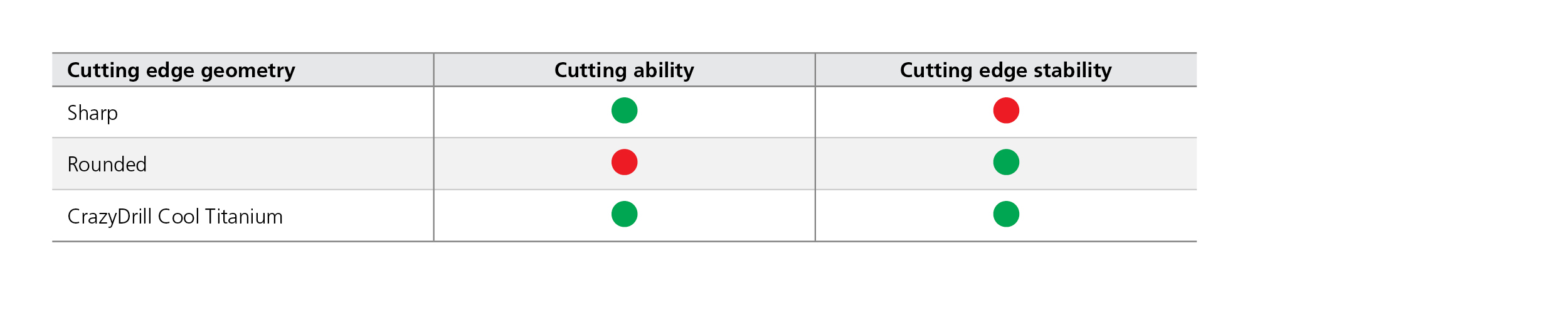

Special cutting-edge geometry with optimum cutting ability and stability

The challenge: Tool jamming as drilling depth increases

As the drilling depth increases, the extreme viscoplasticity of the titanium causes the tool to jam. This in turn causes the tool to break.

The solution: Unique cutting-edge geometry

The solution is sharply ground cutting edges that must be stable at the same time. The new specific cutting geometry masters this balance act. As a result, cutting pressures and temperature are significantly reduced.

Perfect drilling preparation

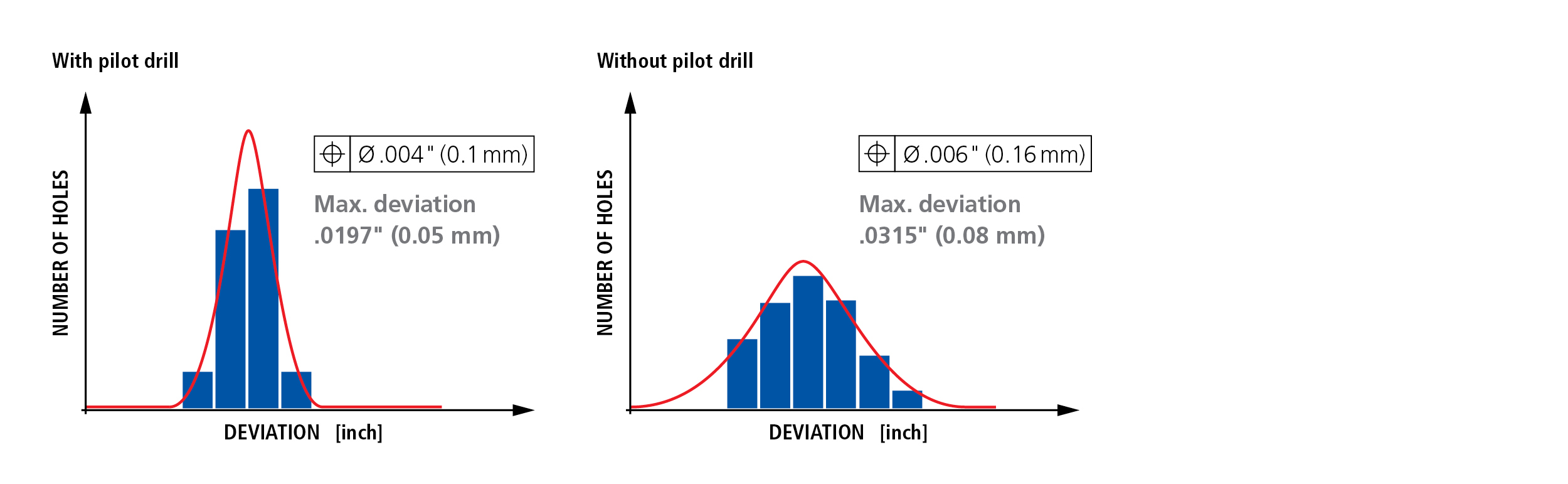

The challenge: Position accuracy

Due to the viscoplastic properties of titanium, an accurate entry point and constant tool guidance during drilling cannot be guaranteed.

The solution: Specific pilot drill

We recommend using the new CrazyDrill Coolpilot Titanium ATC pilot drill (with 90° chamfer) to achieve a high degree of positional accuracy.

Your personal CrazyDrill Cool Titanium

Mikron Tool also offers CrazyDrill Cool Titanium in customer-specific executions:

- Counterclockwise drill

- Drills with varying drill size diameters and lengths for the standard program

Do you need more information about our possibilities? Contact us here.

CrazyDrill Cool Titanium Video

CrazyDrill Cool Titanium Video

For each titanium its drill

For each titanium its drill