For small series and a range of variants

Whether centering, short drilling or precision drilling: with the MiquDrill family Mikron Tool offers three industrial minidrills for every application, provided you are dealing with the production of small and medium batch sizes or a large range of variants. The MiquDrill drilling program focuses on small diameters. All sizes are available from stock and in uncoated and coated versions. The major advantage: diameter increments at every 0.01 mm (.0004ˮ).

The three MiquDrill drill bits for steel are:

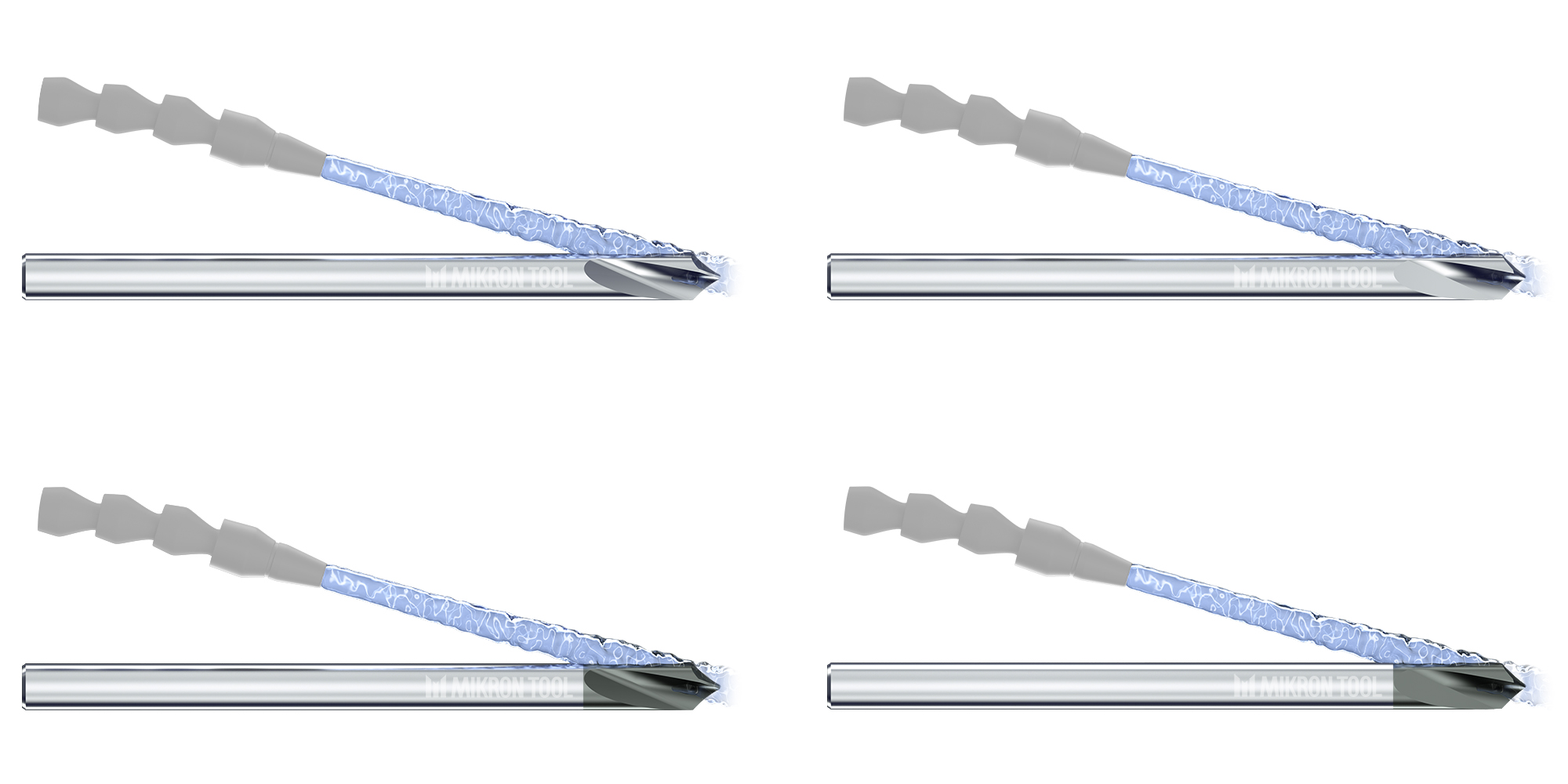

MiquDrill Centro, the NC drill in the diameter range of 0.5 mm (.0197ˮ) (for follow-up drilling from diameter of 0.1 mm (.0039ˮ)) to 6 mm (.236ˮ), optionally with 90° or 120° tip angle. This is available in coated and uncoated versions.

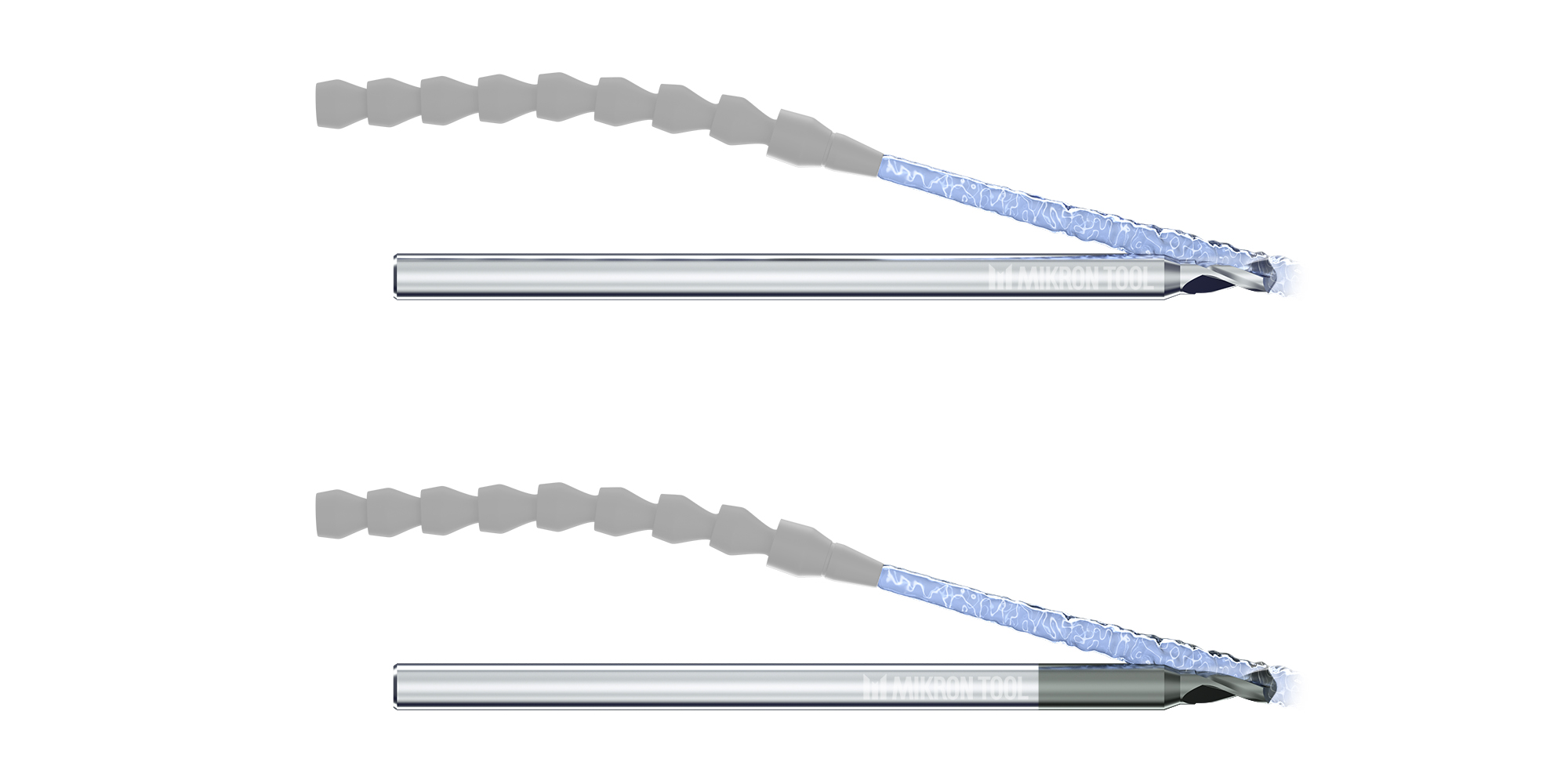

MiquDrill 200, suitable for the finishing of short holes or preparation of deep holes. Available in diameters of 0.1 mm to 1.5 mm (.0039ˮ to.0591ˮ) (drill Ø 0.1 mm (.0039ˮ) to 0.29 mm (.0114”) uncoated, from drill Ø 0.3 mm (.0118ˮ) also coated), with usable lengths between 1.4 x d and

2.4 x d (depending on the diameter).

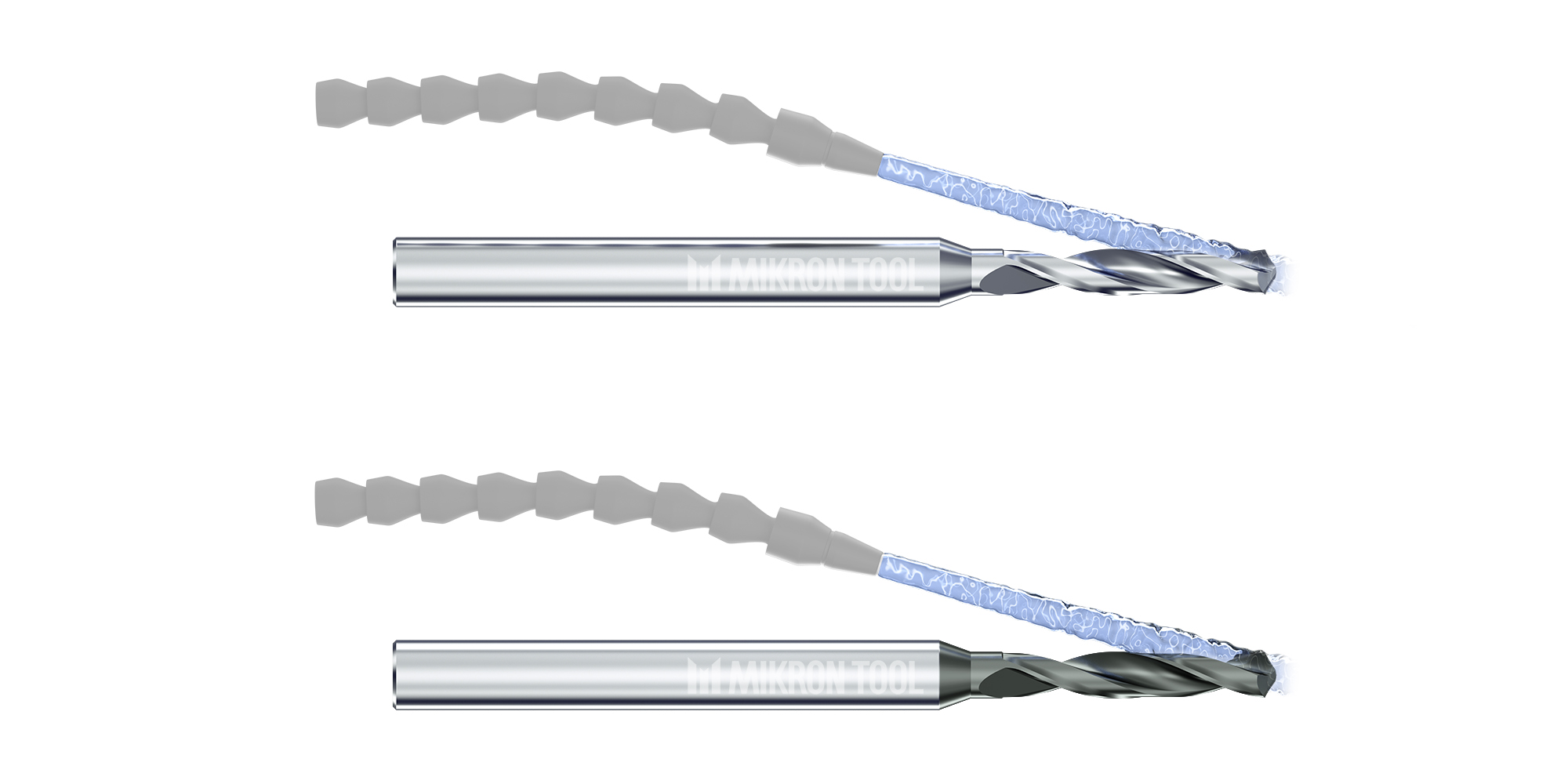

MiquDrill 210, the precision drill for micro-machining is available in diameters of 0.1 mm to

3 mm (.0039ˮ to .118ˮ) (drill Ø 0.1 mm to 0.29 mm (.0039ˮ to .0114”) uncoated, from drill

Ø 0.3 mm (.0118”) also coated), usable lengths between 2.4 x d and 8.0 x d (depending on the diameter).

MiquDrill - the right drill in the right place

The MiquDrill product line of micro drill bits offers proven Mikron Tool quality in the machining of small and medium batch sizes and for few holes in individual work-pieces. These solid carbide industrial drills are therefore the ideal complement to the high-performance CrazyDrill line. They guarantee the same first-class quality and reliability. MiquDrill drills, performing at similar feed rates as HSS drills, reach a significantly longer tool life and are also considerably faster due to their higher cutting speed.

The MiquDrill program consists of the following three standards:

MiquDrill Centro

MiquDrill Centro starts the process by drilling and simultaneously creating a 90° or 120° chamfer. It prepares a precisely positioned follow-up hole in the diameter range of 0.1 mm to 6 mm (.0039ˮ to .236ˮ). It centers perfectly even for the smallest drilling diameters from 0.1 mm (.0039ˮ) and up. This best drill bit for steel (alloyed and unalloyed), cast iron, stainless steels, titanium and other nonferrous metals is universally applicable and is also the ideal partner of MiquDrill 210. MiquDrill Centro is available in diameters of 0.5 mm (.0197ˮ) (for follow-up drilling from a diameter of 0.1 mm (.0039ˮ)) to 6 mm (.236ˮ) in coated or uncoated versions.

Click here to go directly to MiquDrill Centro / Articles

MiquDrill 200

Executing finished short holes in one step or preparing deep holes, those are the strengths of MiquDrill 200. It is the ideal tool for the perfect execution of a short borehole between 1.4 x d and 2.4 x d. As a pilot drill it guarantees a high degree of position accuracy and accurate cylindrical guidance for the subsequent deep-hole tool. Its diameter range goes from 0.1 mm to 1.5 mm (.0039ˮ to .0591ˮ) and it is also available with coating starting from Ø 0.3 mm (.0118ˮ).

Very small diameter increments of 0.01 mm (.0004ˮ) are available from stock.

Click here to go directly to MiquDrill 200 / Articles.

MiquDrill 210

The geometry of the small drill MiquDrill 210 is especially designed for micro-machining at drilling depths between 2.4 x d and 8.0 x d. These are achieved with few chip removal cycles (pecks). The universal drill is available in the diameter range of 0.1 mm to 3.0 mm (.0039ˮ to .118ˮ). The coated version (from a diameter of 0.3 mm (.0118ˮ)) is the solution for higher requirements such as longer life and/or shorter machining times even with difficulties materials.

Very small diameter increments of 0.01 mm (.0004ˮ) or 0.05 mm (.0019ˮ) are available from stock.

Your personal MiquDrill

Mikron Tool also offers MiquDrill in customer-specific variants:

- Drills for hardened steel: Standardized up to 50 HRC, upon request up to 55 HRC

- Counterclockwise drill

- Drills with diameters and lengths varying from the standard program

Do you need more information about our possibilities? Contact us here.