CrazyDrill Twicenter

A centering drill with double advantage

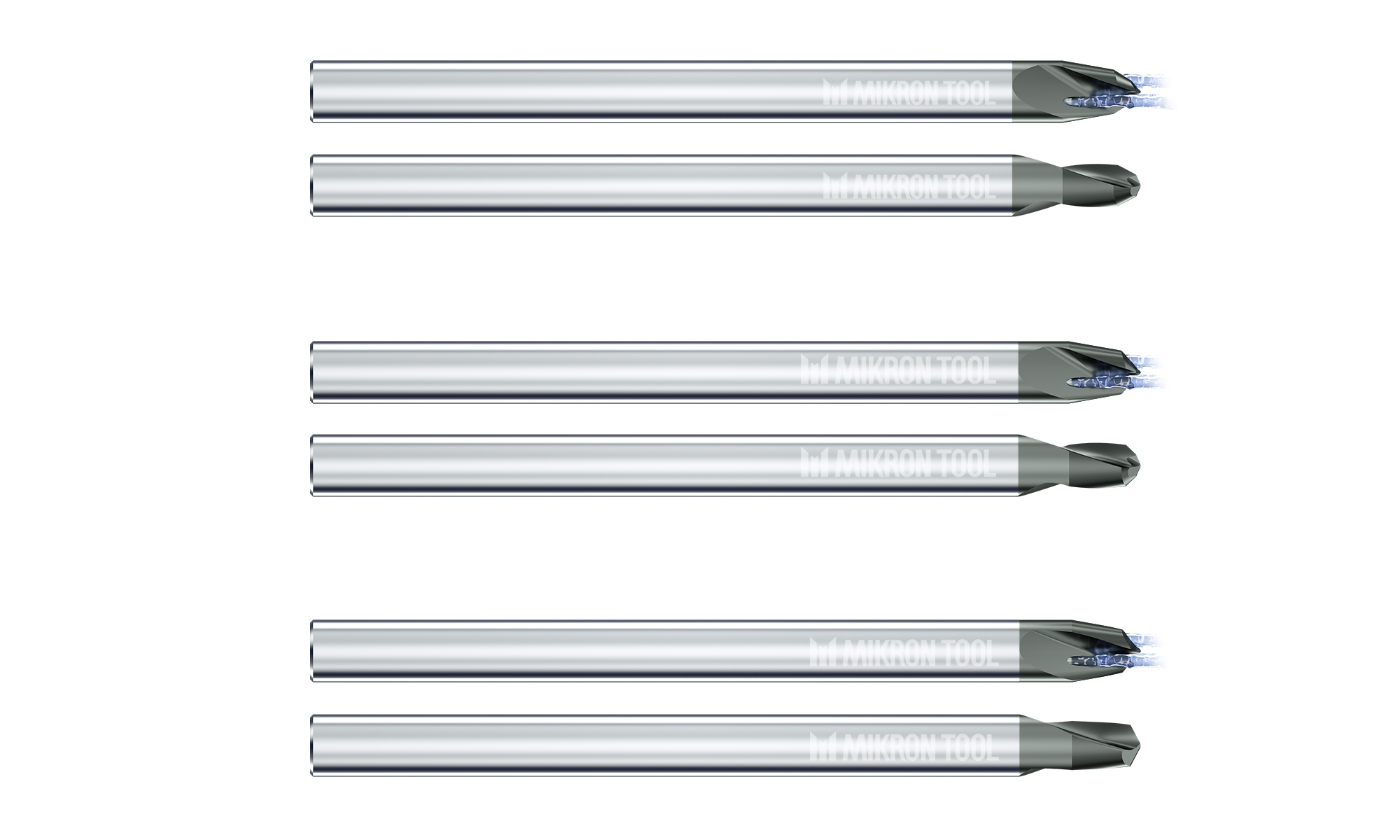

CrazyDrill Twicenter from Mikron Tool is a unique tungsten carbide center drill with a double advantage. This drill with through-tool cooling is designed especially for the center drilling of difficult-to-machine materials. Customary centering drills wear out very quickly due to the strong heat buildup. Because of the through-tool cooling, CrazyDrill Twicenter keeps the machining temperature constantly low and lubricates the drill tip at the same time. The through-tool cooling shows its advantages even when drilling in difficult-to-access spots such as those with protruding edges. The cooling medium arrives at the right spot at all times. CrazyDrill Twicenter can also be used successfully with external cooling. The highest degree of position accuracy is guaranteed in each case.

The extremely short chisel edge and the "double tip" – in chamfers of 60° or 90° with an additional tip angle of 130° – ensure stability and good chip flow. The adapted high-performance coating guarantees longer tool life.

This centering drill, adapted for all types of drilling machines, machining centers and rotary transfer machines, is available from stock in diameters of 0.3 mm to 6 mm (.0118” to .236”) (center) or 1 mm to 10 mm (.0393” to .394”) (chamfer) and for chamfers of 60°, 90° or 120°.

The focus is on "cool" centering with CrazyDrill Twicenter

This center drill with through-tool cooling is also unique in two respects, hence its name: CrazyDrill Twicenter.

Two cooling channels bring the lubricant where it is needed, directly to the drill tip. An additional external coolant supply is unnecessary. This is an advantage when centering in difficult-to-access spots, especially with materials with a poor thermal conductivity value such as stainless steel, titanium or other difficult-to-machine materials.

However, using the center drill as a drill with through-tool cooling is by no means an obligation. CrazyDrill Twicenter remains a first-class centering drill even in "conventional" usage. The second advantage of this tool is a double tip which translates to more stability. In two models the tip angle of 130° is combined with a second angle which makes 60° and 90° chamfering possible in the same drilling run. The 130° tip angle guarantees not only better protection of the cutting edges but also perfect centering of the follow-up drill.

The right high-performance coating increases tool life and makes the center drill an all-around valuable and “cool” tool.

All CrazyDrill Twicenter are perfectly adapted to other types of drills from the CrazyDrill range of products. An example: the two versions with a 130° tip angle constitute the perfect hole preparation for high-precision position accuracy needed for the follow-up machining with CrazyDrill SST-Inox.

The center drill is available from stock in diameters from 0.3 mm to 6 mm (.0118” to .236”) (center) or 1 mm to 10 mm (.0393” to .394”) (chamfer).

Comparison to the standard centering drill

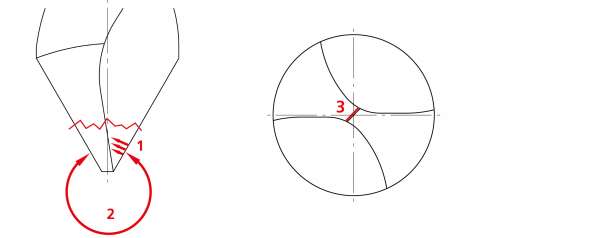

Traditional design:

- Poor chip removel: risk of failure.

- 60° / 90° point angle results in insufficient cutting speed and high pressure on the point: risk of breakage.

- Large web requires high penetration force and causes high pressure on the point: risk of breakage.

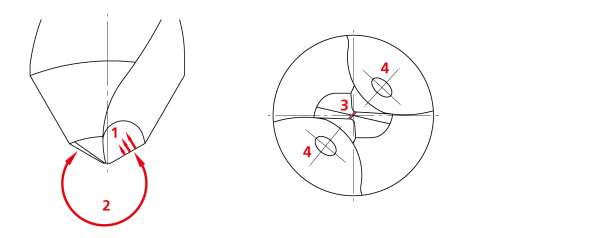

CrazyDrill Twicenter:

- 130° point angle favors chip evacuation.

- 130° point angle reduces the pressure on the point.

- Short web reduces penetration force on the point.

- Through tool coolant supply guarantees optimal cooling and lubrication.

Your personal CrazyDrill Twicenter

Mikron Tool also offers CrazyDrill Twicenter in client-specific executions:

- Drill bits for hardened steel: Standardized up to 50 HRC, upon request to 55 HRC

- Counterclockwise drill

- Center drills with diameters, lengths and chamfering angles varying from the standard program

Do you need more information about our possibilities? Contact us here.

CrazyDrill Twicenter Video

CrazyDrill Twicenter Video

Centering for deep holes in difficult materials

Centering for deep holes in difficult materials