New dimensions when milling

difficult-to-machine materials

CrazyMill Cool Square / Corner radius with four flutes and integrated cooling channels in the shaft is an innovative end mill, developed by Mikron Tool, for pre-machining and finishing of stainless steel, titanium alloys, CrCo and super alloys. It’s specially adapted for the milling of pockets and walls in linear ramping or helical interpolation. Its strengths are, on the one hand, high removal rates, on the other hand high precision (perpendicularity) and surface quality.

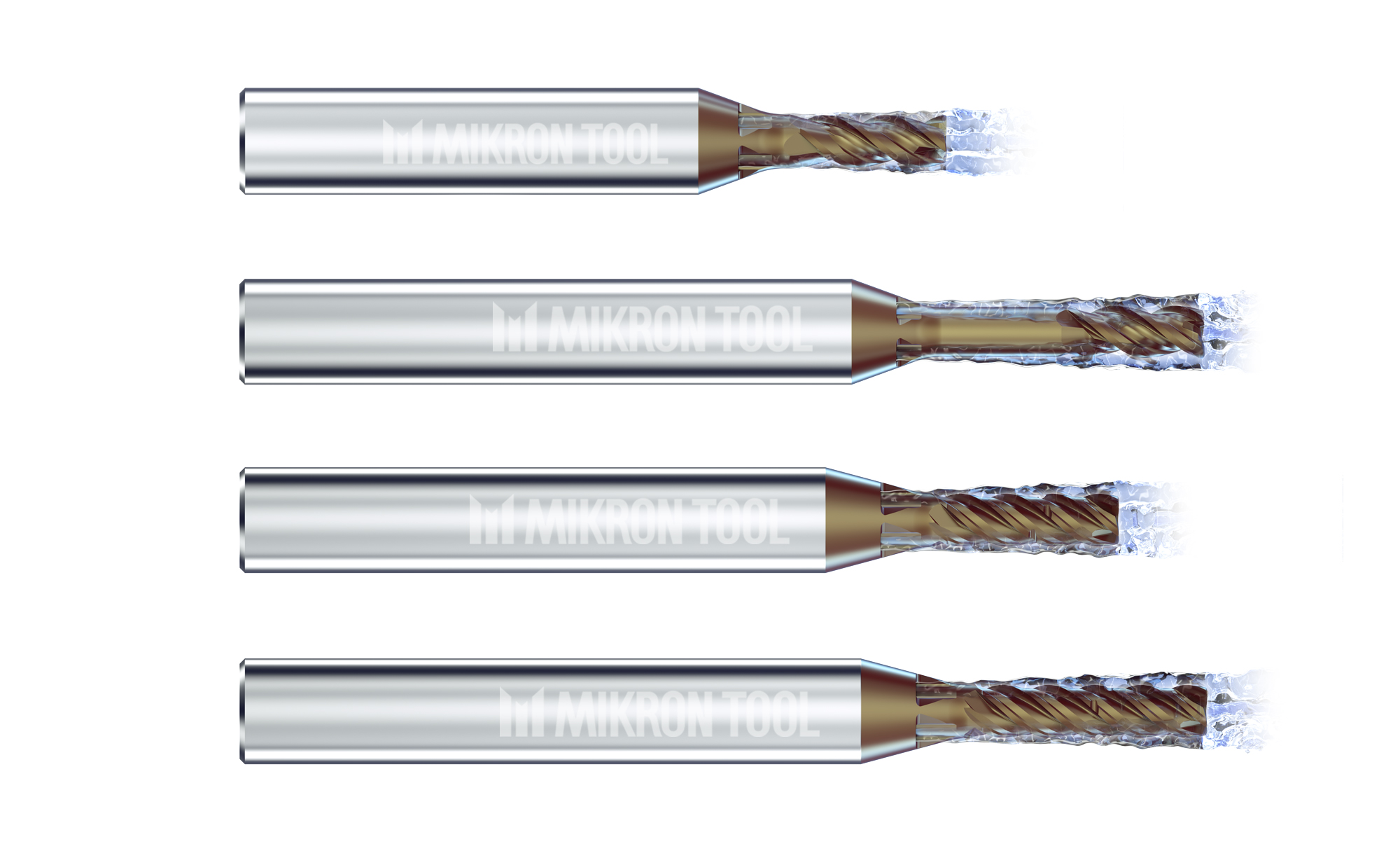

Four versions of cylindric (small protection phase of 45°) and toric (corner radius) micromills with four teeth are available in the diameter range from 1.0 – 8.0 mm (.039“ – .315“, fractional inches available) and for milling depths up to 2 x d, 3 x d, 4 x d and 5 x d.

CrazyMill Cool Z4 – Pre-machining and finishing with one single tool

A milling cutter for pre-machining and finishing of stainless steel, titanium alloys, CrCo and super alloys: this is CrazyMill Cool Z4, the solid carbide end mill with four flutes and shank integrated cooling, available in the diameter range from 1.0 up to 8.0 mm (.039“ up to .315“, fractional inches available). Its innovative chip-breaking design guarantees short chips and a perfect chip evacuation.

Thanks to this perfect chip control and elements such as:

- Micro-grain carbide

- Frontal cutting geometry

- High-performance coating

- Integrated cooling

this innovative end mill guarantees time and cost savings, a reliable process, high precision and excellent surface quality.

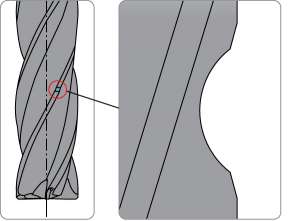

New chip-breaking concept

For the long versions (M and N) an optimized chip-breaking concept guarantees short chips and perfect chip evacuation. Resulting in perfect surface quality and a clearly improved tool life

Micro-grain carbide

The specially developed micro-grain carbide meets all requirements in terms of mechanical properties as rigidity and tenacity. The robust solid carbide shank guarantees stable and vibration-free milling. High precision and extraordinary surface quality are achieved.

Cutting geometry

The innovative cutting geometry is specially designed for reducing vibrations, machining time and to improve the surface quality. The frontal cutting geometry with the specially designed expanded chip collection has been optimized for linear ramp and helical interpolation milling with steep ramp angles.

Due to the robust lateral cutting edge, especially in the long versions (M and N), high tool rigidity is obtained. Therefore, feed rate reduction when finishing is not required.

High-performance coating

The new high-performance coating eXedur SNP is heat- and wear-resistant. Due to an extremely low friction coefficient and reduced affinity to steel, there is no material buildup on the cutting edges and chips are prevented from jamming in the flutes. The result is a long tool life.

Through-tool cooling channels

Three to five cooling channels running through the shaft, which exit on the tool shaft cone (milling tools with 4, 6, 8, 10, 12 mm (.157”, .236”, .315”, .394”, .472“) ensure that the coolant jet flows along the tool diameter and guarantee a constant and efficient cooling of the cutting edges. Hence the highest cutting speeds and maximum performance ap are achieved plustargeted flushing of the chips and highest surface quality are guaranteed.

Your personal CrazyMill Cool Z4

Mikron Tool also offers CrazyMill Cool Z4 in customer-specific executions:

- Milling cutters for hardened steel: Standardized up to 50 HRC, on request up to 55 HRC; this milling tool is not adapted for special hardened steel (over 55 HRC)

- Milling cutters with varying diameters, lengths and teeth to the standard milling program / sizes

Do you need more information about our possibilities? Contact us here.