CrazyDrill Cool for drilling deep holes

and challenging machining conditions

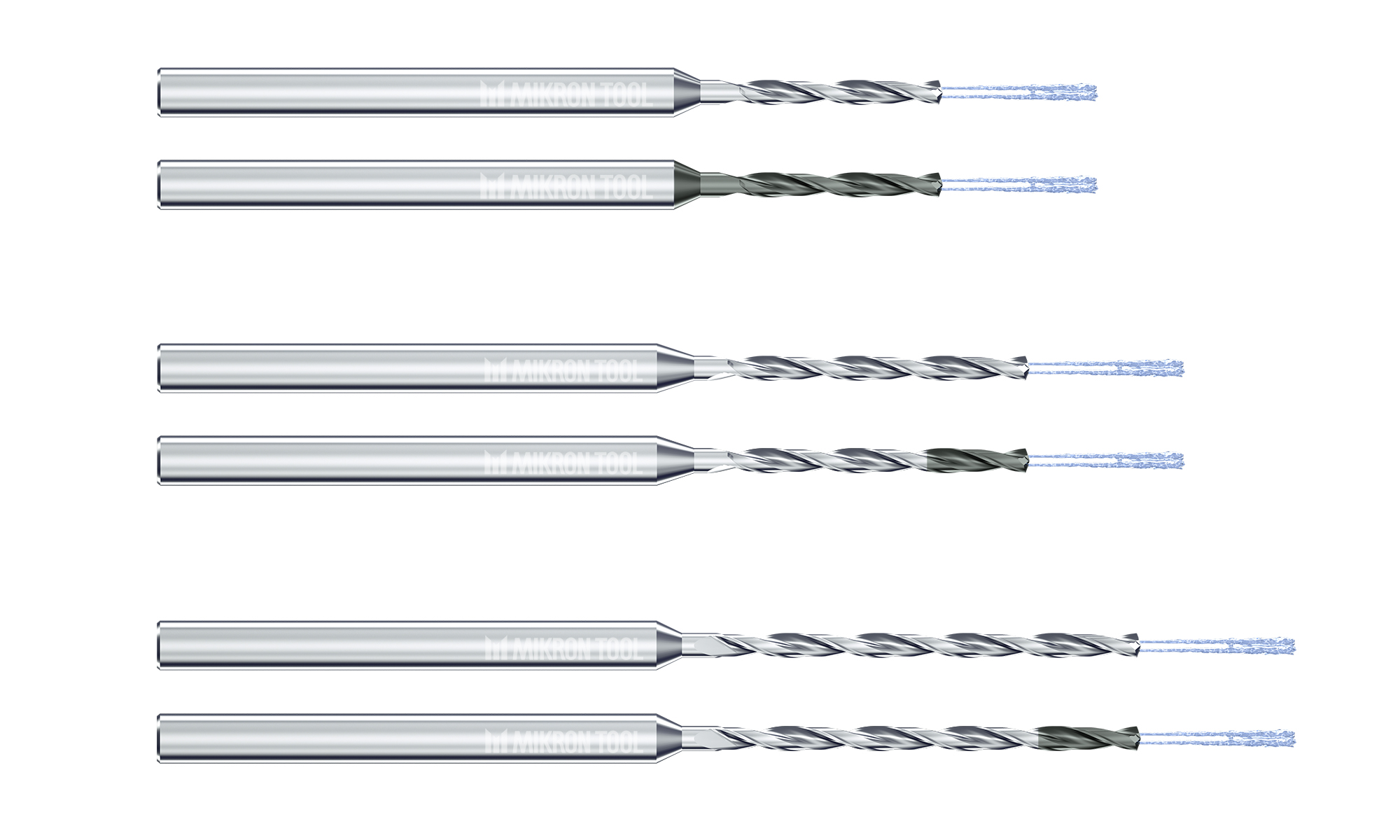

The small drill with through-tool cooling CrazyDrill Cool from Mikron Tool also resolves drilling problems in difficult-to-machine materials. The combined use of a pilot drill (solid carbide drill bits CrazyDrill Pilot or CrazyDrill Crosspilot) and the small drill with through-tool cooling CrazyDrill Cool allows drilling depths of up to 15 x d (other standard lengths: 6 x d and 10 x d) and this in drill size diameter ranges of 0.75 mm to 6 mm (.030” - .236”, coated version in fractional inches available). A shaft-integrated power chamber (up to a drill diameter of 2.95 mm / .116”) allows a more efficient coolant supply directly to the drill tip results in higher drilling speeds and tool life. A double advantage! In addition, the drilling concept of the CrazyDrill Cool is an alternative to the long and costly deep-hole drilling methods using single-lip drills (gundrill).

The smart solution for deep-hole drilling – CrazyDrill Cool

CrazyDrill Cool is used everywhere where long drills are needed to create deep and accurate holes. The drilling concept from Mikron Tool is especially designed for deep holes and is based on a two-stage principle. Centering and pilot drilling is carried out in one step with two types of drill bits: CrazyDrill Pilot or CrazyDrill Crosspilot. CrazyDrill Cool then reaches the maximum drilling depth in one or more pecks (depending on material). By means of fine-tuned tolerances the long drill is not only guided very well in a cylindrical bore but also produces a hole with the best quality. On inclined surfaces the combination with CrazyDrill Crosspilot works best allowing center drilling with an inclination angle of up to 60°.

Two spiral cooling channels leading up to the drill tip supply the cutting edges with coolant even at lower pressure due to the power chamber in the shaft (up to a drill diameter of 2.95 mm / .116”). Oil volume that is three times greater flows through the shaft at the same pressure, allowing high drilling speeds and guarantees better tool life and more efficient chip removal.

The special cutting geometry of CrazyDrill Cool affords optimal chip flow. The need to remove chips depends on the material to be machined and the drilling depth (see cutting data chart). A clearly defined drilling process allows a high degree of process reliability which combined with fast drilling speeds produce time-savings compared to conventional tooling.

To be able to machine nonferrous metals as well as high-quality and difficult materials successfully with CrazyDrill Cool, the small drill is available with or without coating depending on need. For example, the uncoated variant of this through coolant drill is best suited for drilling alumimum.

CrazyDrill Cool can replace expensive deep-hole drilling (for example with gun drilling machine) up to a depth of 15 x d in the drill size diameter range of 0.75 mm to 6 mm (.030” - .236”, coated version in fractional inches available). Greater productivity is thus reached without having to invest in expensive manufacturing systems. Thanks to the high surface quality further finishing processes such as reaming are often not necessary..

It is generally known that machining tungsten carbide or grinding carbide blanks with through-tool spiral cooling channels represent a special challenge. Mikron Tool has specialized in grinding the carbide raw material in such a way that the tool is not weakened and remains stable despite the internal cooling channels.

These high-grade blanks with through-tool cooling channels are used when manufacturing CrazyDrill Cool. Drill regrinding and recoating are possible from a drill size diameter of 1.4 mm (.055”) and increase the cost-effectiveness of this tool.

Your personal CrazyDrill Cool

Mikron Tool also offers CrazyDrill Cool in client-specific executions:

- Best drill bits for hardened steel: Standardized up to 50 HRC, upon request up to 55 HRC

- Counterclockwise drill

- Drills with varying diameters and lengths for the standard program

Do you need more information about our possibilities? Contact us here.