Mikron Tool launches its new engineering services worldwide

- The global launch of Mikron Tool's CrazyService products turns the company into a holistic partner. Now customers can also benefit from engineering services with unique technological approaches.

Customer projects have a long tradition at Mikron Tool. In recent years, the number of inquiries from the machining industry from a wide variety of areas has increased sharply, always looking for the most suitable drills and milling cutters or more efficient machining strategies. Initially, Mikron Tool provided advice and carried out tests to support sales. Now Mikron Tool has decided to offer this type of customer support as a service and is launching the new CrazyService Products worldwide. This means the company now puts its machining expertise at the disposal of its customers. An important step for the company and its partners.

In every crisis there is an opportunity

In 2008 the world was shaken by one of the worst crises. Companies like Mikron Tool, which were and are extremely successful in the automotive industry, faced one of the greatest challenges in the company's history.

Even though the automotive sector has already gone through difficult phases in the previous decades, the situation 2008 situation proved to be even worse. The reason: the trigger for the worst crisis in the automotive industry was the global financial crisis, which led to bank closures and high levels of government debt, pushing the overall economy close to the abyss. But at Mikron Tool it was always the case that there is an opportunity in every challenge. Rethinking was required.

Specialisation in machining of the most difficult materials

Mikron Tool reacted to the crisis with new ideas. So far, the product portfolio was oriented towards the machining of steel components, which are the preferred choice in the automotive industry. Now came the time to open new markets in order to overcome dependence on this industry. The stroke of genius: Mikron Tool turned to the processing of materials that are difficult to machine, so-called super materials such as stainless and heat-resistant steels, super alloys, titanium, and cobalt-chromium alloys. The big advantage was that there was no existing offering of high-performance tools with smallest diameters. Therefore, Mikron Tool extended its research and development work in this area to achieve the opening of new market sectors.

From R&D department to competence centre

To this end, Mikron Tool invested continuously in a Technology Center at the Agno site, which is developing into one of the most modern test centres for the machining in the micro range. This, with a range of machines consistently streamlined for high-performance machining of demanding materials. As a result, Mikron Tool has acquired an incomparable level of knowledge in terms of tool manufacture, materials science, and process technology.

Thanks to this competence, even delicate customer projects can be processed in many sectors more and more successfully. In fact, an increasing number of inquiries are coming from medical technology, aerospace, and the watchmaking industry. Especially here, demanding components made of difficult materials are daily business.

In addition, regular training courses for employees, sales partners and customers are held at the Technology Center, as are topic-related events and technology days. And that in a real-life environment of high-performance machining. The R&D department at Mikron Tool has established itself as an important competence centre.

Technological support

Initially, Mikron Tool supported its customers in performing tool tests and developing customer-specific solutions. Later, tasks became more complex while the number of requests to make entire machining processes more efficient increased.

However, Mikron Tool also sensed that many customers were interested in outsourcing their test projects to free up valuable in-house resources such as machines, manpower and time. This gave rise to the idea of putting the capacities and expertise of the Technology Center at the service of customers.

Perfectly tailored services

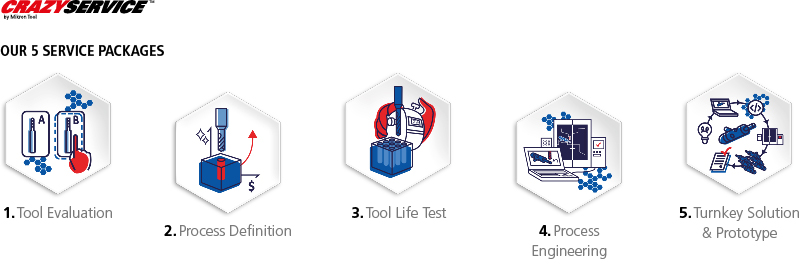

This is how Mikron Tool designed various engineering services, the CrazyService Products, which are perfectly tailored to customer needs: from tool evaluation, optimisation, or redefinition of a process to the complete project including prototype or pilot series for product or process validation. Always under the condition that the preferred solution offers the customer clear added value.

What can customers expect?

Customers can expect professional project management. Consistent from the offer to detailed expertise. Because company needs differ greatly, various levels of service packages were deliberately developed, which enable transitions to remain fluid. What begins with a simple drilling or milling test can end with a complete study of an entire process. Mikron Tool endeavours to always seek out ground-breaking solutions according to the following motto: nothing is impossible!

What does the tool life test determine?

Customers can use this service to obtain estimates of tool costs per workpiece produced. Or to discover the most economic tool solution for their applications.

An example: the service life of a tool needs to be determined. The aim is to determine the ideal cutting parameters vc and vf (cutting speed and feed). The criterion is usually wear mark width (WMW) or, if applicable, chipping on micro-cutting edges. Based on the determined service life of the tool and the operating costs, an economic feasibility calculation can then be performed for the process. Customers receive a detailed report featuring tool evaluation, cutting data and possible recommendations for alternatives.

A field report from medical technology sector

Alberto Gotti, Head of the Technology Center, explains another service that offers complete solutions and prototyping by way of a practical example:

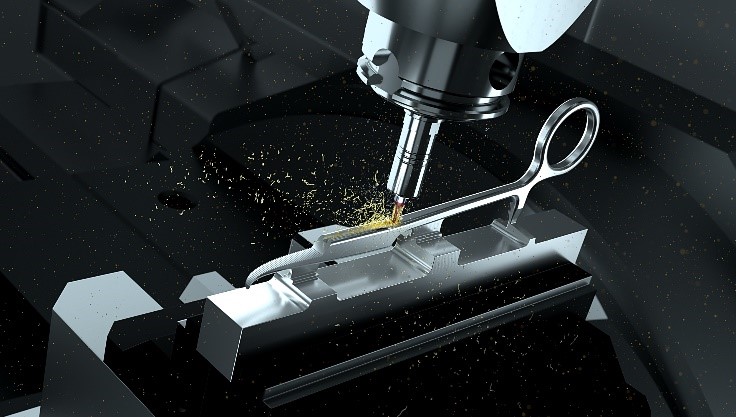

“During project work, we always try to find the most efficient solution, meaning we have to sometimes think outside the box. We succeeded in doing this, for example, when manufacturing a haemostatic clamp.

High standards as an incentive

Customer requirements are clearly defined: radically reduced production times, complete production in a single clamping process, reduction of supports, optimal surface quality and burr-free edges. This presented a real challenge. The material: 17-4PH martensite stainless steel. It offers excellent corrosion resistance, wear resistance and hardness and is therefore popular for use in surgical instruments. Unfortunately, when it comes to machinability, it isn’t such a popular choice. The whole project was a real challenge, actually just the way we love it.”

All parties must be taken into account

In order to get the best out of the production for this medical instrument, the entire environment must be given due consideration: tools, machine, cooling lubricants, tool holders, workpiece clamping and the CAD/CAM programming. And Mikron Tool has this competence. Because the desired results can only be achieved through coordinated interaction of all participants. And that is remarkable: the machining time was reduced by 46% by the machining specialists (from 65 to 35 minutes) and the required surface quality of Ra 0.4 µm was significantly undercut by achieving 0.2 µm.

The customer receives a densely bundled technology package

For this medical instrument, Mikron Tool has developed a completely new manufacturing strategy while adhering to high-quality standards. After the completion of the project, the customer received the entire technology package, which included a detailed report, the machine programme, and prototypes. On request the customer's employees can also be trained by Mikron Tool.

Conclusion: Mikron Tool is expanding its product portfolio

With the global launch of CrazyService Products, Mikron Tool is significantly expanding its product portfolio. The Crazy Service Products stand for professional project management with unique technological content. Alberto Gotti: “And we always remain true to the principle: our passion for quality and top performance flows into every project. Our customers’ success is our goal “.