Three new “crazy” high - performance cutting tools

- Mikron Tool, a world leader in micro-machining of difficult materials, presents three new solid hard metal tools for the AMB (hall 3, booth A83) and ITMS 2024 (West building, level 4, booth 431580).

Mikron Tool, a world leader in micro-machining of difficult materials, presents three new solid hard metal tools for the AMB (hall 3, booth A83) and IMTS 2024 (West building, level 3, booth 431580). The high-performance bit CrazyDrill Titanium TN / TK, for all types of titanium, and the two high-performance mills CrazyMill Cool CF and CrazyMill Cool SF, specially designed for delicate components. With these three products, Mikron Tool has set new benchmarks for high-performance micro-machining.

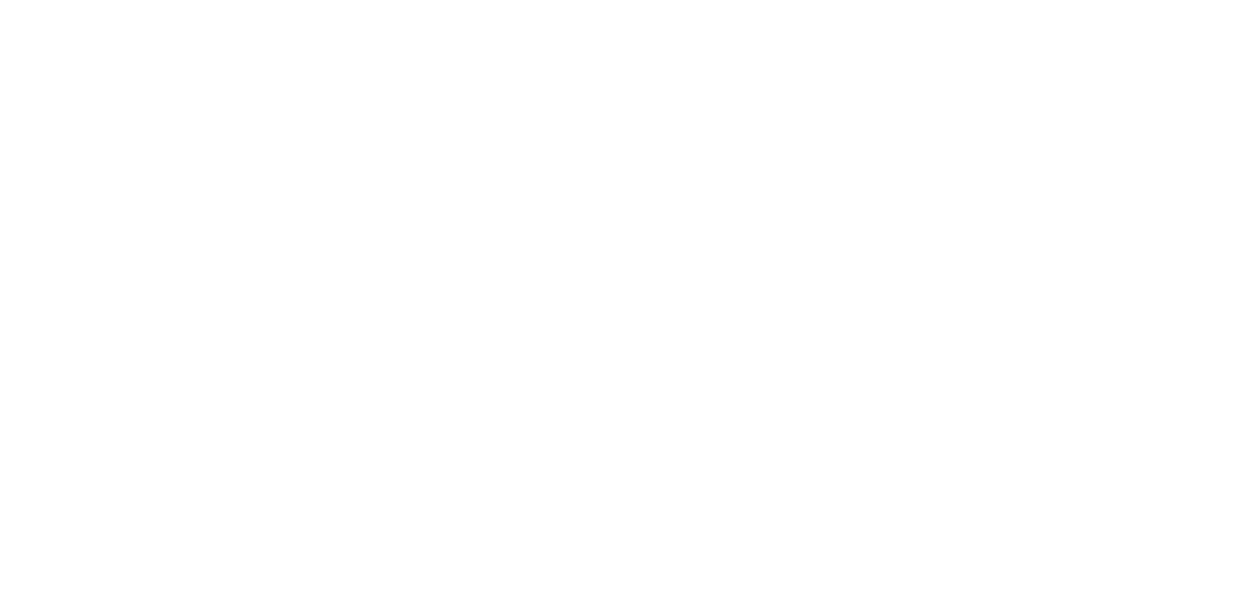

The CrazyDrill Titanium TN/TK microdrill has been developed especially for drilling in all titanium alloys, including pure titanium (!), at diameters from 0.2 to 2 millimeters and depths of 3 x d and 6 x d. It can already be used from 15 bar internal cooling, so a high-pressure cooling lubricant system is not absolutely necessary.

The design of the new CrazyDrill Titanium TN / TK microdrill includes the following features:

- A tip geometry tailored to all titanium grades, which guarantees a low axial cutting force and, together with the designed drill outer profile, ensures maximum drilling precision

- Polished grooves for reliable chip removal

- Coating specially designed for titanium material drilling

This means the high-performance CrazyDrill Titanium TN / TK bit is capable of drilling all titanium alloys and even pure titanium with high process reliability. The CrazyDrill Titanium TN/TK provides maximum feed rates, very long service life, optimal process reliability, and very high drilling precision.

High-performance milling with excellent surface quality, up to ground finish quality

Two new high-performance mills have been developed for milling applications. One is the “Chatter-Free” (CF) CrazyMill Cool CF and the other is the “Super Finishing” (SF) CrazyMill Cool SF.

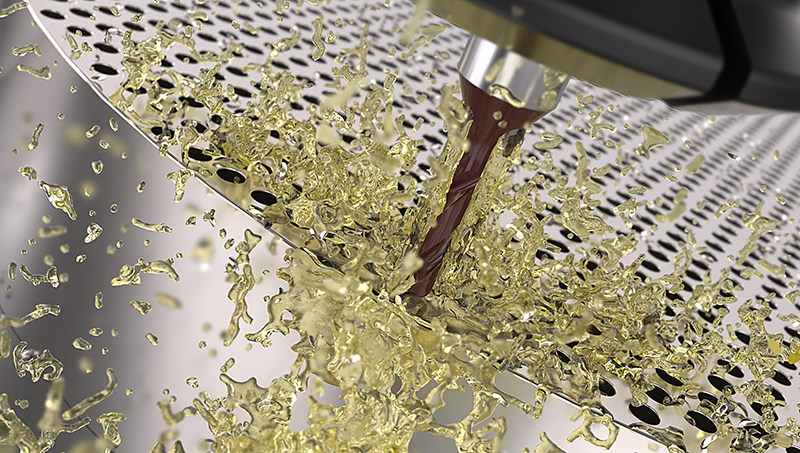

CrazyMill Cool CF - Chatterfree

The CrazyMill Cool CF is a high-performance micro mill designed for very high machining rates and capable of handling very challenging, delicate component structures. A perfect balance between cutting angle, clearance angle and cutting edge conditioning results in a low radial cutting force and thus ensures the best form and squareness tolerances even at maximum depth of cut.

Its specific cutting geometry, combined with a dynamic milling process, makes it the ideal mill for delicate, thin-walled parts, or for parts that are not stable when clamped, which is a particularly common occurrence in the medical field (bone plates) and aerospace industry (structural components), as well as the watch industry. CrazyMill Cool CF is also very efficient, precise, and runs quietly when cutting grooves, insets, or other large volume machining tasks.

The mill is available immediately in diameters from 1 to 8 millimeters and two different full cutting lengths (3 x d and 4 x d).

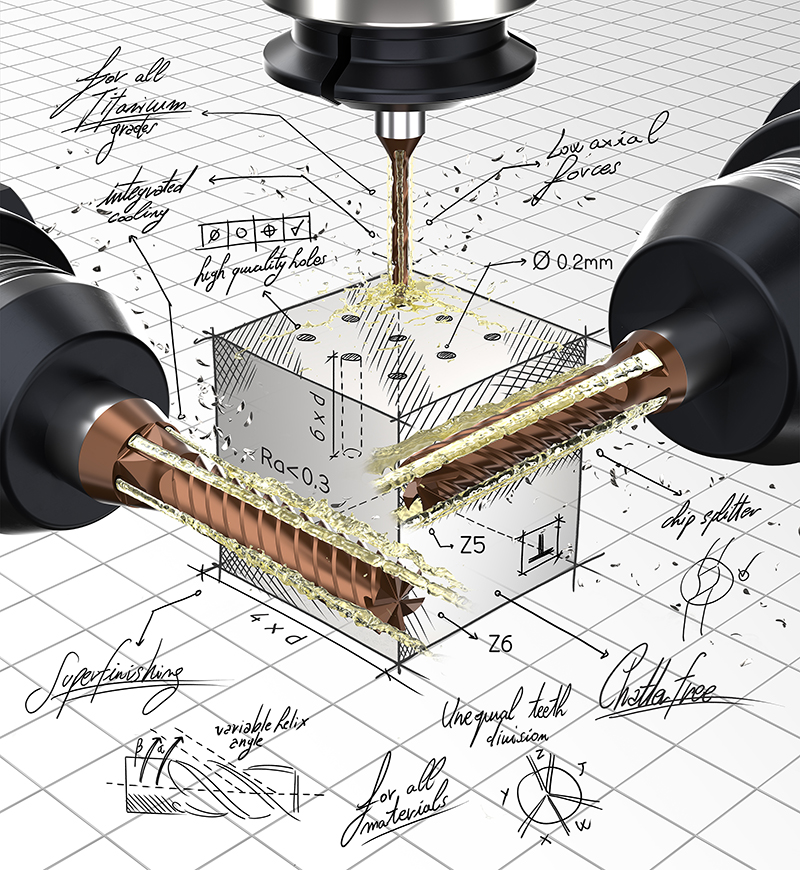

CrazyMill Cool SF – Superfinishing at less than Ra 0.3 µm

The CrazyMill Cool SF has been developed as a superfinishing mill that produces milled surfaces at a grinding or polishing level of quality, with roughness of less than Ra 0.3. This greatly reduces the effort required for polishing. The CrazyMill Cool SF also produces excellent surface quality of less than 0.3 µm in (chromium) steel, lead-free brass, copper, cobalt-chromium, and Inconel.

The CrazyMill Cool SF is available immediately in diameters from 1 to 8 millimeters and two different full cutting lengths (3 x d and 4 x d).

Visitors at AMB and IMTS can see the newest “crazy” developments at the Mikron Tool booth and see test workpieces first-hand. In brief: The “Madmen of Agno” are always happy to get visits from users who are looking for “crazy manufacturing solutions.”