Precision Watchmaking at EPHJ 2025 with Mikron Tool

- Join us on June 3-6 at the Palexpo Geneva - booth F115

Mikron Tool sets new benchmarks for high-performance micro-machining. The Swiss manufacturer of precision cutting tools presents new solutions for high-end watch manufacturing at the EPHJ 2025. Discover "Crazy Tools" for watch cases, crowns, gears, and more. Uncompromising quality for luxury timepieces.

Switzerland has always been synonym of the highest precision watchmaking: 95% of the world’s most prestigious watches are made by Swiss Manufacturers.

Renowned for their innovation, technical precision, and aesthetic excellence, Swiss luxury watches encompass status, traditional craftsmanship, and cutting-edge design.

The manufacturing of these exclusive, desirable timepieces demands the world’s best production processes.

Mikron Tool embodies the same taste for precision made in Switzerland. The Swiss cutting manufacturer specializes in the design and creation of tools – renowned as “Crazy Tools” for their exceptional performance - tailored to meet the demanding expectations of high-end, high-precision watch manufacturing.

By combining state-of-the-art technology with an unwavering commitment to quality, Mikron Tool ensures its products are the perfect match to the unique challenges of the industry. To meet these demands, the tools feature the smallest sizes, with a strong emphasis for the machining of materials typical in the watch industry such as stainless steel, titanium, precious metals an leadfree brass.

The natural connection between the Swiss watch industry and Mikron Tool lies in their shared commitment to unrelenting innovation and excellence. When purchasing a luxury watch, consumers seek the perfect timepiece, and the engineers at Mikron Tool are dedicated to delivering the best cutting tools for these challenging manufacturing demands. And this is precisely why the world’s best watch brands regularly choose to work with Mikron Tool.

The portfolio includes tools and services for manufacturing of many things concerned with watchmaking, with the tightest tolerances and precision down to a few microns, such as plates and bridges, flywheels, crowns, watch cases, base and top elements, wristlets, clasp elements and various other mechanical parts.

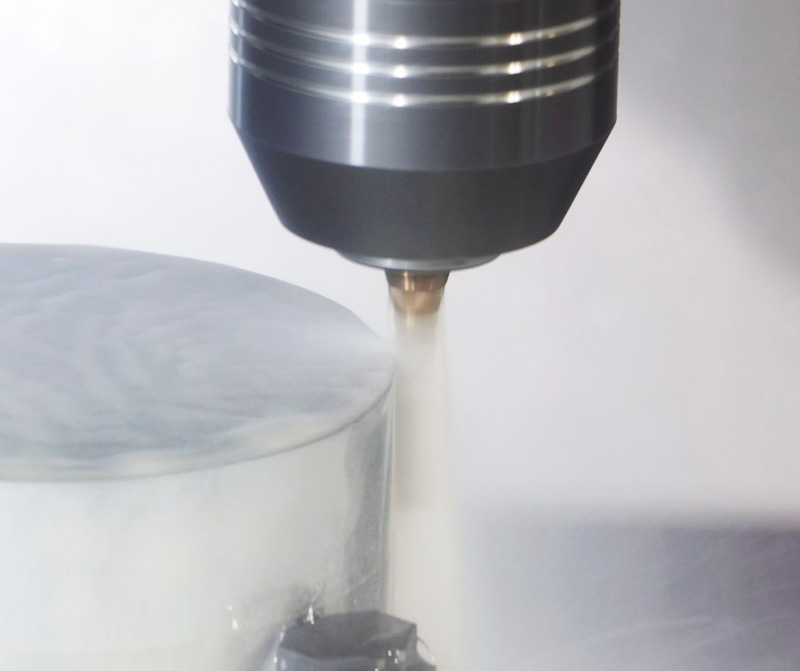

The CrazyMill Cool Micro with through-shaft cooling is a high-performance micro-endmill for roughing and finishing operations with two material-specific cutting-edge geometries: geometry S for stainless steels, structural steels, cast iron, non-ferrous metals and titanium alloys; geometry SX for super and CoCr alloys. Available are the square micro-endmills with three or four flutes in the diameter range from 0.2 – 1.0 mm and for milling depths up to 3 x d and 5 x d.

The CrazyMill Cool CF is a high-performance endmill designed for very high machining rates and capable of handling delicate component structures. It works with minimal side milling cutting pressure resulting in completely chatter-free machining. The result is an excellent surface quality (Ra 0.5 µm or better).

The CrazyMill Cool SF has been developed as a superfinishing mill that produces milled surfaces at a grinding or polishing level of quality. After machining, the surfaces have an astonishing roughness value of Ra 0.3 µm or better in milling direction and endmill axis direction.

CrazyMill Cool P&S square and corner radius is an innovative, 3-flute mill with in the shank integrated coolant supply ducts which Mikron Tool developed specially for rough and finish milling of stainless steels, titanium, super alloys and CoCr alloys. It is also very well adapted for other materials such as steels up to max. 40 HRC, cast iron, non-ferrous metals and plastics. Based on its ability to plunge directly with up to 1 x d vertically into material, it becomes a “plunge-mill” i.e. “drill-mill” or “milling drill” for metal and is especially suitable to mill grooves, pockets and faces in smallest spaces in general and specifically for keyways (feather keys).

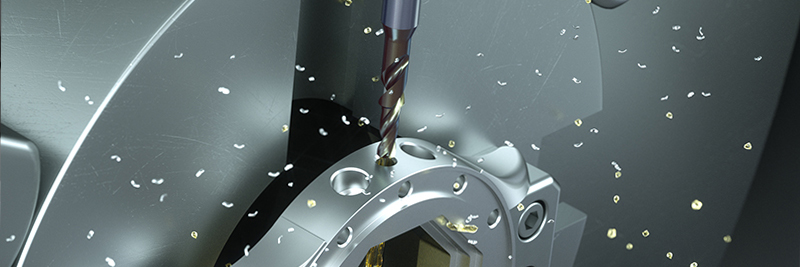

CrazyDrill Crosspilot for direct drilling on inclined surfaces up to maximum inclined angle of 60°, is available in diameters from 0.4 mm to 6.35 mm.

CrazyDrill Coolpilot is a pilot and short drill with an integrated cutting edge for 90° chamfer for stainless steel, heat-resistant and CoCr alloys in the diameter range of 1.0 mm to 6.35 mm and for a drilling depth up to 3 x d. It’s an ideal complement to CrazyDrill Cool SST-Inox.

CrazyDrill Pilot SST-Inox is a pilot drill for pilot and short holes for stainless steel and heat-resistant and CoCr alloys in the diameter range of 0.2 mm to 2.0 mm and for drilling depths up to 3 x d. They are coated, have integrated cooling channels (innovative cooling concept), a cutting edge for 90° chamfering and a digressive helical flute.

With CrazyDrill SST-Inox type IK Mikron Tool offers an exclusive drill with integrated cooling for drilling in stainless steel up to 12 x d and in the diameter range of 0.2 to 2 mm. This drill can tackle not only stainless steels, but also chromium-cobalt alloys, heat-resistant steels and even lead-free brass. This drill’s geometry differs significantly from other products available in the market today.

CrazyDrill Cool SST-Inox is a twist drill type for stainless steels, heat- and acid-resistant steels and CoCr alloys in the diameter range from 1 up to 6.35 mm and for drilling depths from 6 x d to 40 x d. The tungsten carbide drill is designed with internal helicoidally arranged cooling channels which bring up to four times more coolant volume to the drill tip. The new cooling system, the new design of tip and flute as well as the innovative coating enable drilling in one single step up to a drilling depth of 40 x d with high performance in terms of quality, tool life and machining time.

CrazyDrill Coolpilot Titanium ATC is a pilot and short drill with an integrated cutting edge for 90° chamfer for titanium alloys in the diameter range of 1.0 to 6.35 mm and for drilling up to 3 x d. This drill is also equipped with its innovative through-tool cooling channels. Because of the difference material properties between the different titanium grades, with CrazyDrill Cool Titanium ATC (for titanium alloys) and PTC (for pure titanium), Mikron Tool offers a drill perfectly tailored to the material in question in the diameter range of 1.0 to 6.35 mm and for drilling depths of 3 x d to 10 x d.

Even for small diameters, with CrazyDrill Titanium TN / TK, Mikron Tool offers a micro drill perfectly tailored to pure titanium and titanium alloys in the diameter range of 0.2 to 2 mm and for drilling depth of 3 x d and 6 x d.