Mikron Tool welcomes DMG MORI delegation

- On 12 October 2023, the President of DMG MORI CO, LTD, Dr (Ing.) Mori, visited Mikron Tool’s headquarters in Agno

The machine tool manufacturer DMG MORI and Mikron Tool collaborate closely within the DMQP partnership. In October, Dr Eng. Mori, President of DMG MORI CO., LTD., and members of his management team visited Mikron Tool’s headquarters in Agno to enhance their cooperation. The goal is to maximize the benefits of the synergies resulting from the expertise of the leading machine tool manufacturer and the Dr Eng. Mori of the application and tool specialist.

The customer takes centre stage

The focus is clearly on added value for the customer. The committed collaboration between DMG MORI’s global Excellence Centers and the machining experts at Mikron Tool’s Technology Center provides design engineers with access to holistic and tested manufacturing solutions. This enables them to seamlessly implement of entire processes in their production and make investments without unnecessary risks.

Strong partnerships result in technological knowledge

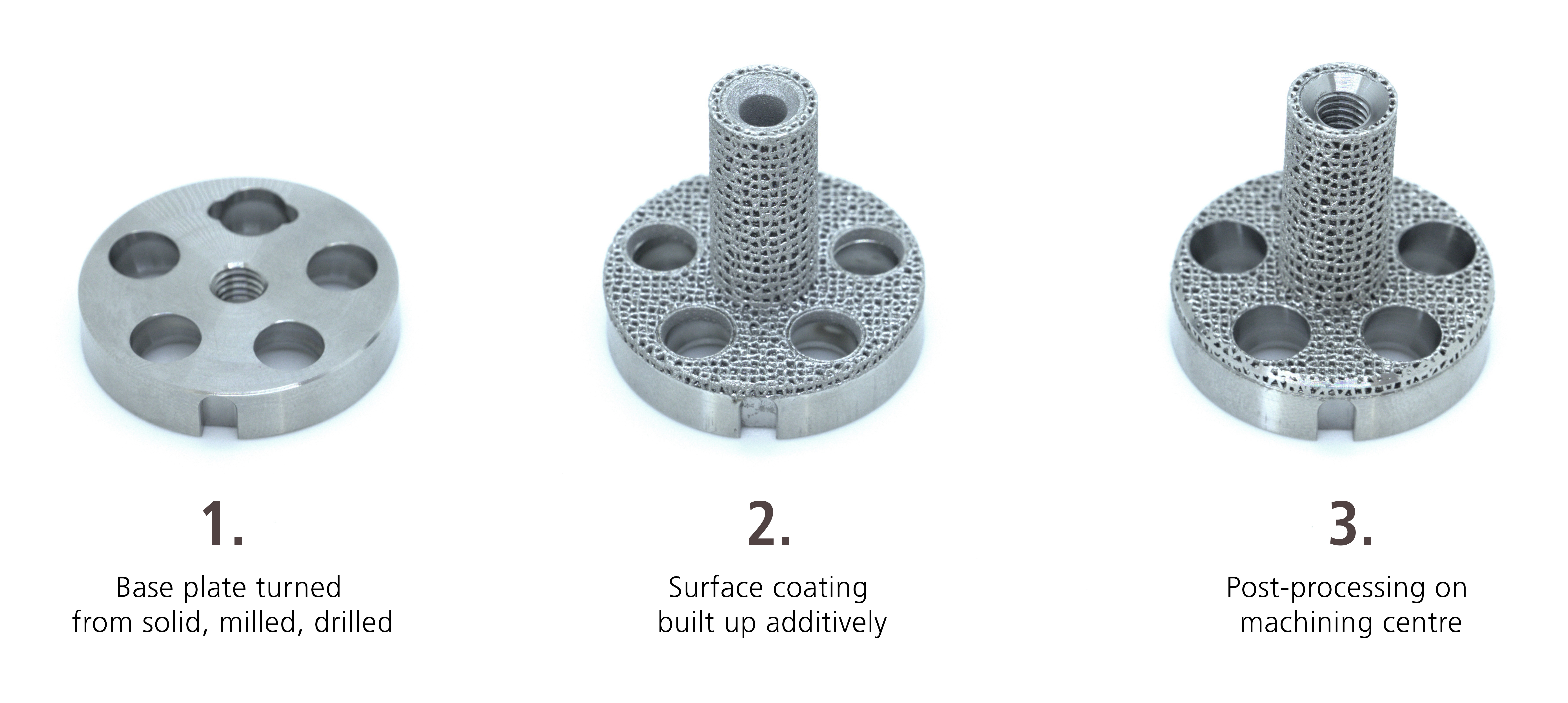

Mikron Tool and DMG MORI go one step further. At the recent Medical Days at Mikron Tool’s Technology Center this spring, the technology-driven companies presented a collaborative project with the support of Motorex, the cooling lubricant experts. Together, they addressed the actual theme of hybrid production in medical technology. This innovative manufacturing approach, blending traditional machining with additive manufacturing, underwent testing using a medical technology component crafted from grade 5 ELI titanium. The results were then compared with established processes like CNC machining and additive manufacturing.

To ensure that the test was realistic, DMG MORI supplied the Mikron Tool Technology Center with a LASERTEC 30 DUAL SLM for additive manufacturing, employing a laser melting process. Alongside the existing NTX 1000 (turning/milling center for six-sided machining) and a DMP 70 (5-axis machining center), the hybrid process chain was fully realized:

Hybrid manufactured part:

Testing the hybrid production of a glenoid base plate was shown to important guests from Italy, Switzerland, and Germany. The result demonstrated that its cost-effectiveness is heavily dependent on the specific application and will play a vital role in the future of metalworking. Mikron Tool and DMG MORI experts contributed significantly to this extraordinary team effort. It is only possible thanks to technological partnerships between DMG MORI and Mikron Tool.

Testing the hybrid production of a glenoid base plate was shown to important guests from Italy, Switzerland, and Germany. The result demonstrated that its cost-effectiveness is heavily dependent on the specific application and will play a vital role in the future of metalworking. Mikron Tool and DMG MORI experts contributed significantly to this extraordinary team effort. It is only possible thanks to technological partnerships between DMG MORI and Mikron Tool.

Further expansion of the collaboration

The outcome of the October meeting between DMG MORI and Mikron Tool was the worldwide expansion of collaboration in the medical technology sector and intensify the collaboration in other areas such as mould making and aerospace. We will further enhance our collective presence at international trade fairs and other tech events to highlight our comprehensive services for turnkey and tested production projects, as well as technological innovations, to our customers.

It was a valuable and trend-setting meeting that underpins the trusting partnership between the two companies.